MOBILIS ELITE, MULTI-CONDUCTOR ELECTRIC RAIL

The most suitable solution to meet our customers requirements and bring power to move.

Mobile electrification system from 20A up to 200A, 4 or 5 poles.

Features and benefits of the multiconductor rail MOBILIS ELITE

The solution for the most various applications

Are you looking for a conductor bar system from 20 to 200A ? MOBILIS ELITE is the solution.

Whatever your requirement in mobile electrification is, this multiconductor bar, equipped with 4 or 5 conductors and its large choice of options will suit you.

Easy to set up

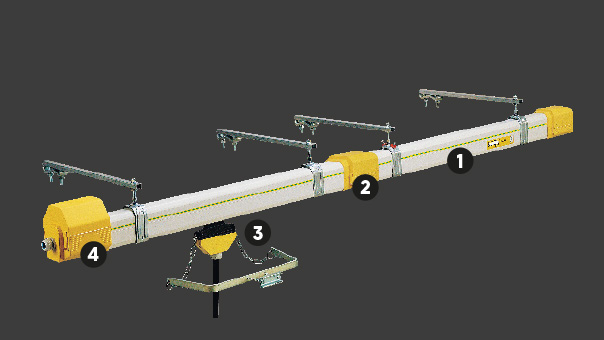

Select 9 components to get an MOBILIS ELITE. electrified line.

Our web catalog helps you to prepare your inquiry in just a few minutes.

Modular systems

- Tailor made curved systems.

- High temperature version (+75°C).

- Protection lips for dusty environment.

- And: ventilation element, interruption element, introduction gate, transfert elements, maintenance tools.

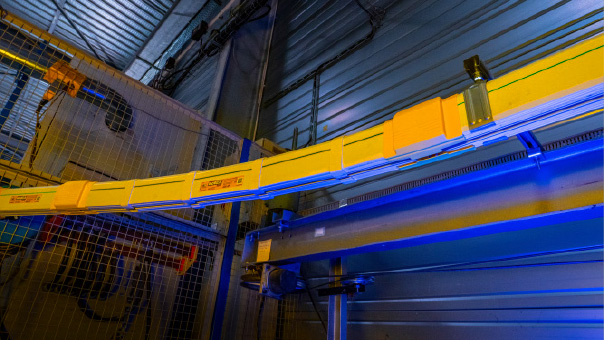

The busbars are used as well inside as outside.

You can take down a busbar system MOBILIS ELITE at any time.

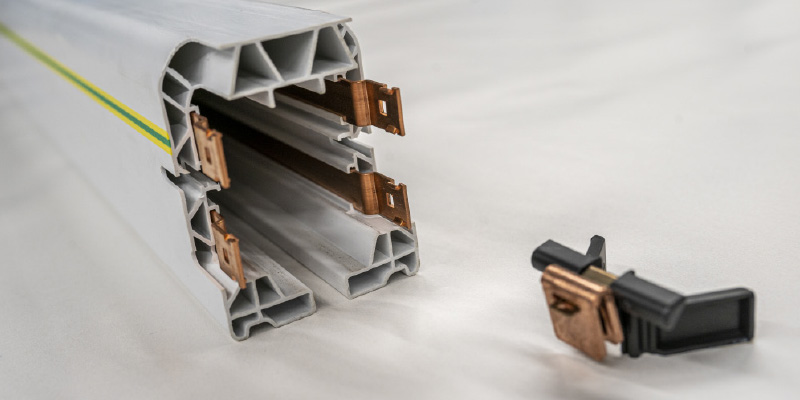

Easy and safe connection

Self breaking screws for an optimal connection.

The ideal torque and the maxi connected surface reduce power drop.

Quick and easy assembly

Just clip the bars into the self aligning sliding hangers.

No tools are required to assembly MOBILIS ELITE accessories.

Safety, reliability, durability

The specific profile of the rail provides stability to the line and is IP23rated so it is finger safe and resistant to rain.

Upkeep requirements are minimized providing lower installation and lifetime maintenance costs.

MOBILIS ELITE – Maximum versatility and modularity

Conductor bar systems ELITE by MOBILIS are mainly used to deliver power to:

- Cranes

- Jibs and hoists

- Automated storage

- Task saving systems

- Theatre stages

- Wastewater treatment or composting plants

- Or many other applications inside or outside

Conditions of use: indoor or outdoor

In case of use in an area open to the public, additional safety measures should be implemented (protection level IP4X required according to EN60204-32).

Busbar, trolley ... - technical features

Construction

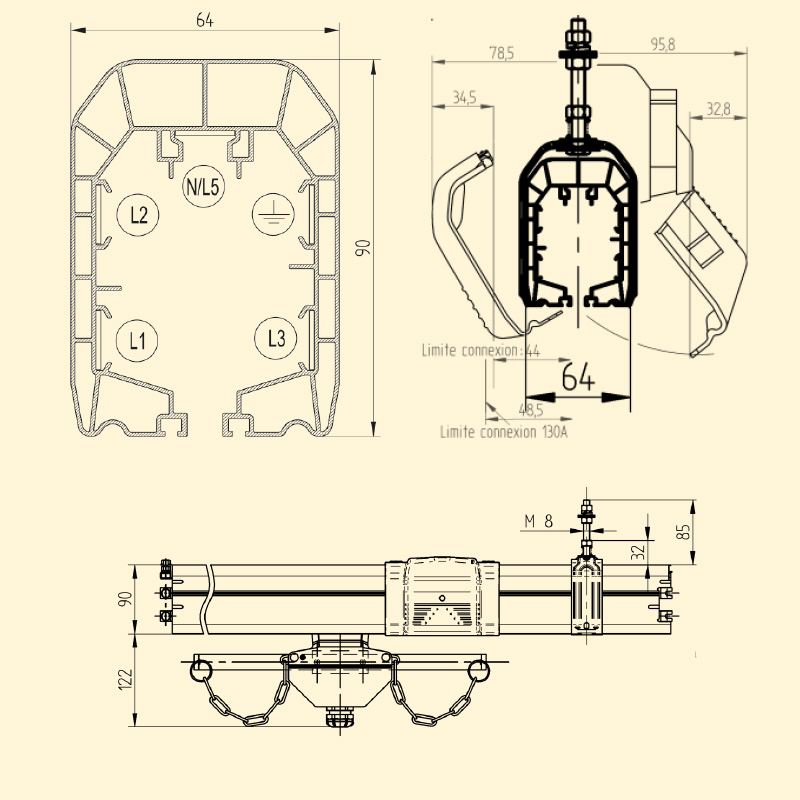

| Profile | Honeycomb PVC compact profile – closed system for a maximum safety. |

| Profile dimensions: | L 64 mm H 90 mm |

| Overall dimensions: | To ease assembly, keep 250mm minimum free space from the busbar |

| Length of the line: | Unlimited with expansion joint(s) Expansion joint required if: – Calibre 20A and L > 140 m – Calibre 40A up to 100A and L > 150m – Calibre 130A up to 200A and L > 250m |

| Flame resistance | All plastic materials are self-extinguishing; they pass successfully glowing/hot line tests under 960°C for elements in contact with live parts and V-0 according to UL-94. |

| Conductors material | 20A: stainless steel 40A up to 200A: copper |

| Maximum speed of the trolleys | 180m/min with high speed trolley for straight lines. 70m/min with articulated trolley in curves. |

| Endurance | Collectors have been tested to run at least 2000km. |

Terms and conditions of use

| Suitable environment | Category 3 of ISO 2081 (outside mild), inside, outside use under rain or dust. A version with 600h resistance under saline mist is available. Please consult. |

| Applicable standards | EN60439-2, EN61439-6, EN60204-32, CE, UKCA |

| Temperature of use | Standard: -30°C … +55°C High temperature: -30°C … +75°C |

| Protection index | IP23 according to EN60529 (assemblied line with all required accessories) |

Electrical performances

| Intensities | 20A, 40A, 60A, 100A, 130A, 160A, 200A |

| Poles | 4 or 5 poles - The ground conductor (PE) is marked on the line by a green-yellow strip. The neutral conductor (N), when present, is located in the top section of the casing. |

| Rated operational and insulation voltage | 750V alternative, 50Hz for standard version 440V alternative, 50Hz for high-temperature version |

| Protection against short circuits | Intensities ≤ 130A: Icw < 10kA Intensities 160 and 200A TR: IPK = 11kA |

| Insulating distance between conductors or between conductors and accessible parts | Distance in the air: 10mm min. Creepage distance: 30 mm min. (according to EN60204-32) |

Intensity according to duty cycle

The intensity of the rail is the minimum admissible value of the rail. According to temperature and duty cycle the admissible value can be higher:

| Temperature of use | Duty cycle | Max. admissible value | |||||

| 40A | 60A | 100A | 130A | 160A | 200A | ||

| 35°C | 80% | 72A | 90A | 117A | 127A | 162A | 211A |

| 40°C | 67A | 86A | 109A | 117A | 155A | 195A | |

| 55°C | 48A | 63A | 86A | 87A | 131A | 140A | |

| 35°C | 100% | 68A | 85A | 114A | 120A | 152A | 184A |

| 40°C | 64A | 82A | 106A | 109A | 145A | 171A | |

| 55°C | 47A | 61A | 82A | 83A | 121A | 126A | |